The US-based company Active Surfaces has produced an ultra-thin perovskite solar panel that can be attached to any curved profile

Founded in 2022 and with an R&D laboratory in Woburn, Massachusetts, Active Surfaces has recently received significant investment for its range of ‘peel and stick’ solar panels. The technology was originally developed to provide lightweight and flexible solar panels for the urban ‘built’ environment, but its products could also be adapted for the marine environment.

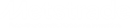

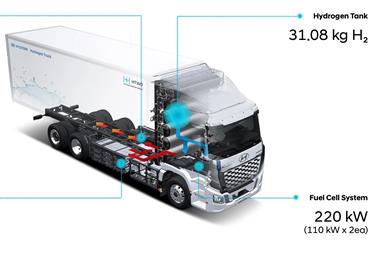

The new solar cells, created as a thin film using roll-to-roll manufacturing techniques, have been refined after a decade if research at the world-famous Massachusetts Institute of Technology (MIT). The process is described as ‘low temperature, automated and low labour, enabling fast iteration, high yield and exceptional capital efficiency compared with conventional silicon’. The perovskite panels are said to give more than 25% efficiency at 1/20th of the weight, so could have applications in masts and sails where conventional panels, even semi-rigid versions, would be less than ideal. The thin curved film design could also follow the contours of a superstructure, or even the tubes of a RIB.

Perovskite is also able to capture more of the light spectrum for conversion to electricity, so the Active Surface panels are claimed to have higher efficiency potential than silicon and better low light and off-angle performance. The domestic-friendly manufacturing base also leads to lower costs, with the minimal use of raw materials. No rare earth materials, for example, are needed in production. The power-to-weight ratio is quoted as 1000W/kg, with a durability of 10 years. The proprietary encapsulation process being used is said to protect against degradation caused by oxygen and moisture, with an advanced coating technology used for uniformity in the film quality. These innovations are expected to overcome the three challenges commonly associated with using perovskite instead of silicon, namely scalability, durability, and cost.

The thin film technology has already attracted inward investment from Japan-based Electric Power Development (J-Power) although no financial details were disclosed. The funding will allow the two companies to collaborate on pilot tests with the new flexible encapsulation process. J-Power seeks to create new businesses by utilizing diverse perovskite solar cell products in various installation environments, and marine could well be on the list. Construction halls could also be a target market, as the company says around 65% of US warehouses don’t have roofs strong enough to support large arrays of aluminium-framed silicon solar panels. The investment follows a US$200,000 grant from the Massachusetts Manufacturing Accelerate Programme (MMAP) to purchase automated equipment to scale up production of the thin film solar panels.

https://www.activesurfaces.xyz

LinkedIn

LinkedIn X / Twitter

X / Twitter Facebook

Facebook Email us

Email us