Hydrotab is a well-established name in the marine industry – renowned for its innovative, powerful and virtually indestructible boat trimming system – but the origins of the ambitious Athens-based company lie in a completely different sector

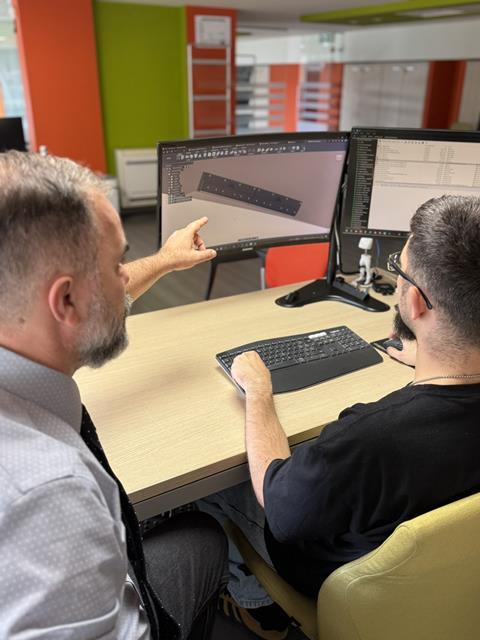

‘My father founded Olympic Engineering Ltd in Athens back in 1969 as a shoemaking machinery company, designing and manufacturing advanced pneumatic systems for shoe production,’ explains Nick Triantafyllis, managing director at Hydrotab Marine engineering.

‘We became known worldwide for our back-part moulders and crimping machines – recognized as the best of their kind globally – because they were fast, precise, and, most importantly, built to last. Many of those machines are still operating today after decades of service.’

That reputation for reliability and precision defined Olympic Engineering’s identity and success, with the company maintaining a simple philosophy – create technology that never fails – a philosophy that eventually led to the creation of its Hydrotab boat trimming system.

PNEUMATIC ENGINEERING

‘As a family, we were passionate boaters,’ recalls Nick. ‘On our own boat, we had one of the early interceptor systems available at the time. It worked well when new, but it was fragile and it didn’t stand up to the real marine environment – a weakness that bothered us. When a system fails at sea, it’s not just inconvenient, it’s unacceptable, so we decided to use what we knew best: pneumatic engineering.

‘We started experimenting. The first prototype used fresh water to inflate a flexible tube that pushed a blade outward from the hull. It was simple but effective. Soon afterwards we replaced the water with compressed air – a decision that changed everything.

‘Air is lighter, faster, and far more reliable, and it can’t corrode, leak, or freeze. It was then that we realized we had created something truly unique – a trim system that was not only powerful and efficient, but also virtually indestructible.

‘That was the birth of Hydrotab – born from engineering discipline, shaped by real boating experience, and designed to eliminate one of the biggest sources of frustration at sea.’

DESIGNED FOR REALITY

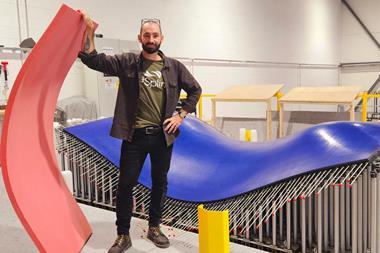

From day one, the company’s goal was to design for reality – not theory.

‘The sea exposes weakness instantly,’ says Nick, ‘and we wanted a system that could take anything nature throws at it. Hydrotab’s pneumatic interceptor technology eliminates the problems found in hydraulic and electric systems. There are no fluids, seals, or pumps to leak or corrode. It’s pure air pressure – clean, safe, and reliable – resulting in a system that is:

- Maintenance-free, with no oil or hydraulics to service

- Corrosion-proof, performing perfectly in saltwater for years

- Instant in response, deploying in milliseconds for smoother control and fuel efficiency

- Compact and easy to install, making it ideal for modern boatbuilding

- Durable, built from marine-grade materials and tested to extremes

- Fairly priced, reflecting our commitment to quality without inflated cost

FROM ATHENS TO THE WORLD

Hydrotab’s evolution from a workshop concept to an international brand was a gradual process based entirely on the success of its performance.

‘We never relied on marketing hype,’ insists Nick, ‘we relied entirely on results. Boatbuilders who tried Hydrotab saw immediate benefits: faster planing, improved stability, reduced fuel consumption and minimal maintenance.

‘Word spread quickly, and today, our Hydrotab systems are installed by respected builders across Europe, the USA and Asia.

‘We grew organically, one partnership at a time, by delivering something every captain values – peace of mind. And behind all this remains Olympic Engineering, the backbone of everything we do today.

‘Every Hydrotab component is designed, machined, and assembled in-house in Greece, under the same roof that once built the world’s finest shoemaking machines,’ adds Nick. ‘That continuity – the same hands, same precision, same philosophy – defines who we are.’

LinkedIn

LinkedIn X / Twitter

X / Twitter Facebook

Facebook Email us

Email us